ClientThe client is a prominent manufacturing workshop in Qatar specializing in producing metal components for various industries, including construction and oil & gas. With a focus on precision and productivity, the workshop required a reliable material handling solution to streamline operations and enhance efficiency. In October, contacted DQCRANES to look for a suitable gantry crane through our website.

ClientThe client is a prominent manufacturing workshop in Qatar specializing in producing metal components for various industries, including construction and oil & gas. With a focus on precision and productivity, the workshop required a reliable material handling solution to streamline operations and enhance efficiency. In October, contacted DQCRANES to look for a suitable gantry crane through our website. Semi Gantry Crane Design FeaturesStructural Design:

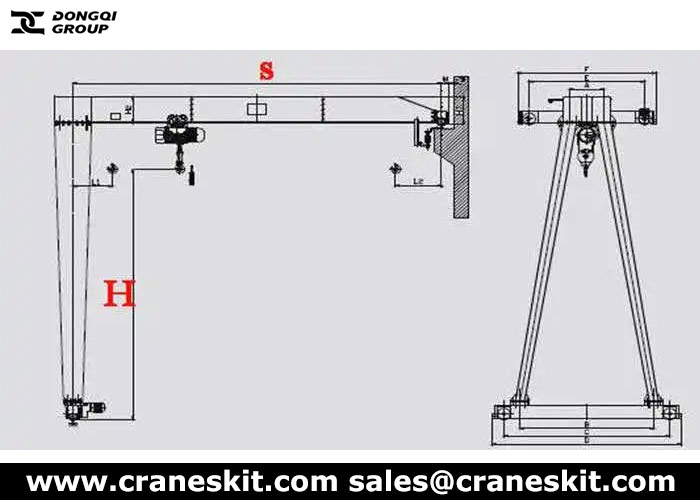

Semi Gantry Crane Design FeaturesStructural Design:

Installation

Installation Gantry Crane Applications in QatarThe adaptability of gantry cranes offered by DQCRANES is an excellent choice for various applications, including:

Gantry Crane Applications in QatarThe adaptability of gantry cranes offered by DQCRANES is an excellent choice for various applications, including:| Welcome Digital Dream Technology support (http://bbs.ddcnc.com/) | Powered by Discuz! X3 |